拖車軸的焊接是一項(xiàng)高要求的任務(wù)

車輛組件的焊縫承受高動態(tài)負(fù)載,因此拖車軸的焊接屬于接合技術(shù)中要求*嚴(yán)格的作 業(yè)任務(wù)之一。為了確保在靈活性不受限制的同時實(shí)現(xiàn)*高水平的部件質(zhì)量,過程安全的 焊接工藝和*新型設(shè)備技術(shù)是不可或缺的前提條件。

兩個相同的焊接單元直接提高靈活度

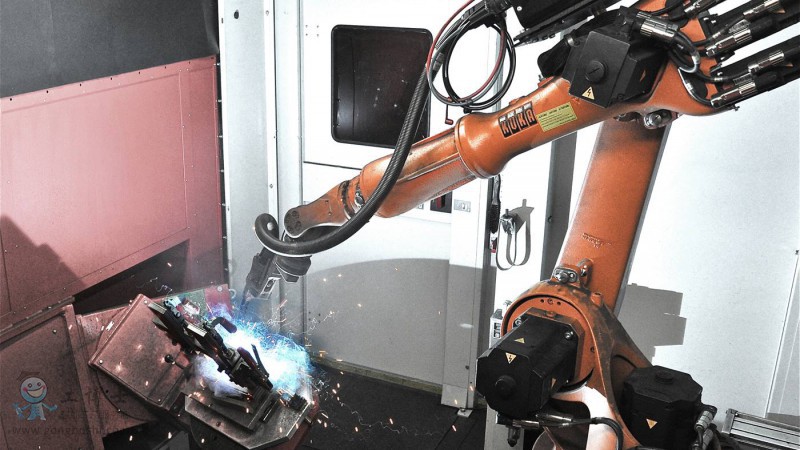

為了生產(chǎn)實(shí)用拖車軸的搖桿、防盜裝置和各種附件,AL-KO 采用了系統(tǒng)集成商領(lǐng)軍企 業(yè) Robolution 的兩個相同的焊接單元。這些工位上生產(chǎn)的主要特點(diǎn)是批量小,10 至 500 件,并且型號眾多。Robolution 通用單元的兩個不同的特殊定位器帶來了令人難以 置信的靈活性,同時通過采用六軸 KUKA KR 16 焊接機(jī)器人確保了卓越的品質(zhì)和生產(chǎn) 效率。

Welding of trailer axles is a highly demanding task

Welds on vehicle components are exposed to high dynamic loadings, as a result of which welding trailer axles is one of the most demanding tasks in joining technology. Reliable welding processes and state-of-the-art production technology are essential prerequisites for guaranteeing maximum component quality at the same time as unrestricted flexibility.

Two welding cells increase flexibility

For its production of rocker arms, anti-theft devices and various add-on parts for commercial vehicle trailer axles, AL-KO relies on two identical welding cells from the leading system integrator, Robolution. Production in these stations is dominated by small batch sizes of between 10 and 500 parts, with an enormous number of variants. The Robolution universal cells with their two different special positioners bring an incredible flexibility to bear, while using the six-axis KUKA KR 16 welding robot guarantees both outstanding quality and productivity.

六軸KUKA

KR 16焊接機(jī)器人具優(yōu)越的速度和質(zhì)量

智能化設(shè)計提高焊接的質(zhì)量

這一**設(shè)備以其 5 軸定位器和一個附裝在設(shè)備縱向側(cè)的特殊定位器 TurnFix 著稱, 可將非生產(chǎn)時間降至極低。 設(shè)備采用了智能化設(shè)計,配備了軌道定位器和 TurnFix,可 使兩個工位在生產(chǎn)時間內(nèi)進(jìn)行平行裝配。六軸 KR 16 機(jī)器人以其速度和**性令人折 服,從而提供了出色的焊接結(jié)果。

極高靈活度的

庫卡焊接機(jī)器人

目前設(shè)備上存有近 100 種不同型式的部件程序。在大多數(shù)情況下,裝調(diào)成另一種 部件型式可在五分鐘內(nèi)完成。部件范圍涵蓋了各種小部件直到*大長度可達(dá) 800 毫米的組件。整個焊接程序以及專用工裝都可隨時從一個設(shè)備應(yīng)用到另一設(shè)備 上。由此實(shí)現(xiàn)了更大的靈活性。庫存和備件管理也十分簡單。當(dāng)設(shè)備出現(xiàn)故障時, 對于特別緊急的焊接任務(wù)可在另一臺設(shè)備上完成,以免浪費(fèi)時間。