The ESP3 vertical immersion sump pump delivers extended pump life over a wide range of applications in chemical and hydrocarbon processing. It is available in many corrosion-resistant materials and with a broad range of options, enabling customers to tailor the pump to site-specific requirements.

Features and Benefits

ASME B73.1 Standard Casing Design is offered in a wide range of materials, including abrasion-resistant high chrome iron, to suit application requirements.

One-piece, Heavy-duty Shaft is ground to a high finish and designed, along with the bearing sizes and API compliant spacing, to produce the highest critical speeds available.

Standard Reverse Vane Impeller offers repeatable performance throughout the life of the pump. And, since liquid exits the back of a reverse vane impeller, wear occurs on the cover instead of the expensive casing. Open impellers are available for stringy or fibrous liquids.

Bearings are properly located to eliminate shaft whip. To suit application requirements, duplex angular contact thrust bearings are mounted externally and sized to handle all pump axial thrust. Radial linesaft bearings, carbon standard, are also available in low-cost bronze, fluted rubber as well as abrasion-resistant PEEK and corrosion-resistant PTFE.

T.B. Woods Sure-Flex Couplings are precision machined and self-aligning.

Large Polypropylene Basket Strainer resists corrosion. Up to four times larger than the impeller eye,the oversized basket lowers velocities and improves suction performance. Metal strainer available.

Factory Flanged Discharge simplifies field piping and is available in a variety of configurations.

Mounting Plate Options

Three optional mounting plate constructions are offered with the ESP3. They are:

Vapor tight – uses a standard lip seal

Vapor proof

–– Withstands 0.34 bar (5 psi) differential pressure

–– Available packed or mechanically sealed

Pressurized

–– Recommended for hazardous and flammable liquids

–– Withstands 3.4 bar (50 psi) differential pressure

–– Available with standard or gas-type mechanical seals

OPERATING PARAMETERS

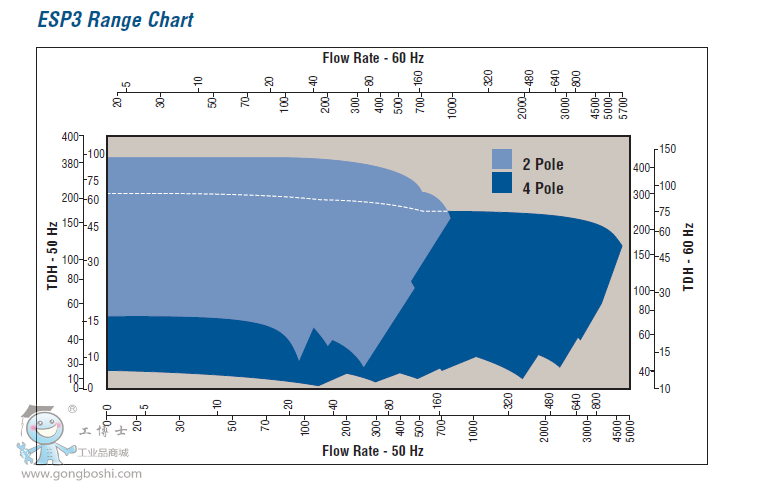

Flows to 1300 m3/h (5700 gpm)

Heads to 90 m (300 ft)

Pressures to 12 bar (175 psi)

Temperatures to 180°C (350°F)

Pit depths to 6 m (20 ft); greater depths achievable with optional tailpipe

更多福斯Flowserve產(chǎn)品和應(yīng)用,煩請(qǐng)登錄www.flowserve-pump.gongboshi.com